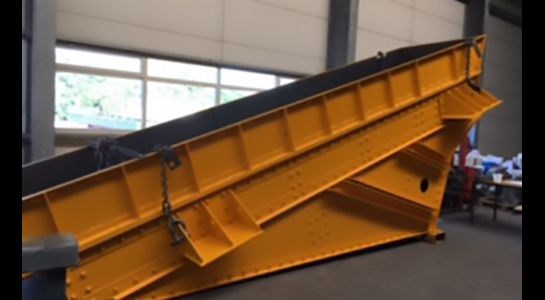

Discharge Feeders

Discharge feeders are a type of continuous conveyor. The drive below the conveyor trough can consist of two counter-rotating vibrating motors or directed exciters. These drives bring the machine into linear vibration and convey the material from the loading point to the discharge.

Discharge feeders are primarily used to remove materials from bunkers or silos. The extremely sturdy construction allows the conveyance of light to heavy, as well as cold to warm materials.

The advantages of a discharge feeder compared to other conveyors:

- very low maintenance

- low wear

- wide drive adjustment range

- replaceable wear lining

Drive: Via unbalance motor or directed exciter

Style: Vibrating feeders have a torsion- and warp-resistant welded construction. Typically, the whole construction is made from S235JR material. The material certificate can be requested. The material thickness varies by construction style and drive placement.

Lining: When conveying highly abrasive materials, wear plates are installed.

The wear plates are screwed in place and are thus replaceable.

Rubber liners can be installed for gentle transport. This is also suitable for transporting material which tends to stick.

Mount: Discharge feeders are usually mounted with temperature-resistant pressure springs to reduce vibration. This mount, combined with the construction, offers maximum insulation against vibration.

Exciter bracket: In particular, the crossbar of the exciter motors requires utmost care during welding. After welding, this crossbar is annealed to be free of stress, then mechanically processed.

Special equipment: The vibrating feeder can be equipped with heating elements to minimise deposit build-up. The heating elements are mounted below the hopper. The control unit is built into the control cabinet by the customer.