Drum polygon sieves

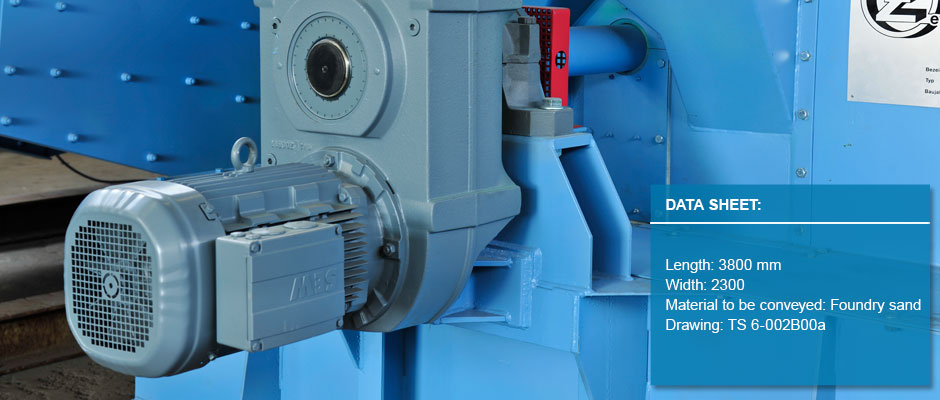

Drum polygon sieves are used to screen material as quickly and efficiently as possible where only a confined space is available.

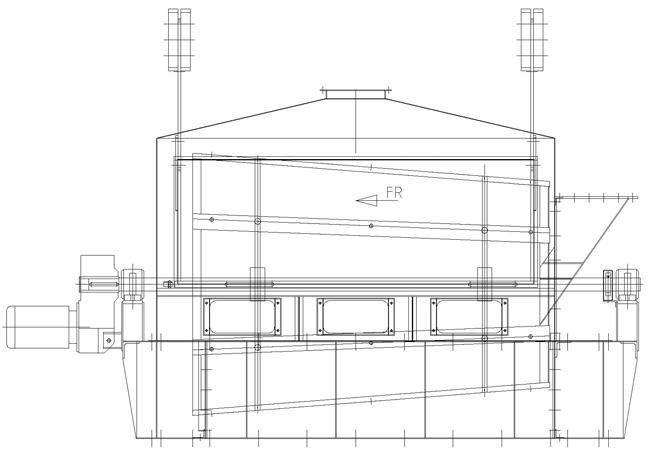

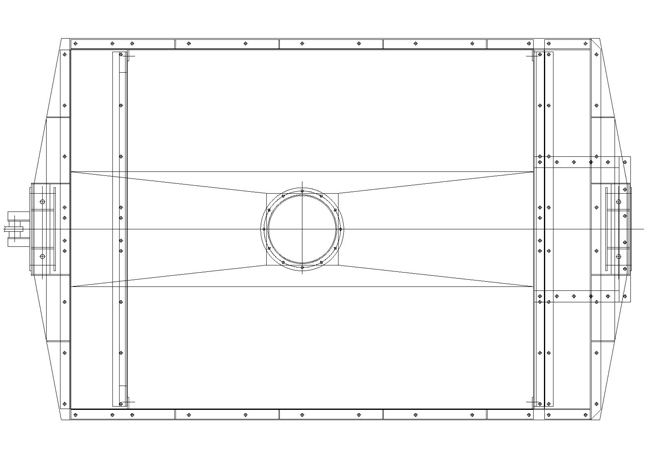

The material that is conveyed for screening is fed via the delivery chute into the sieve drum, which increases in size towards the discharge outlet.

The cone shape of the sieve drum ensures that the material conveyed is transported to the discharge outlet.

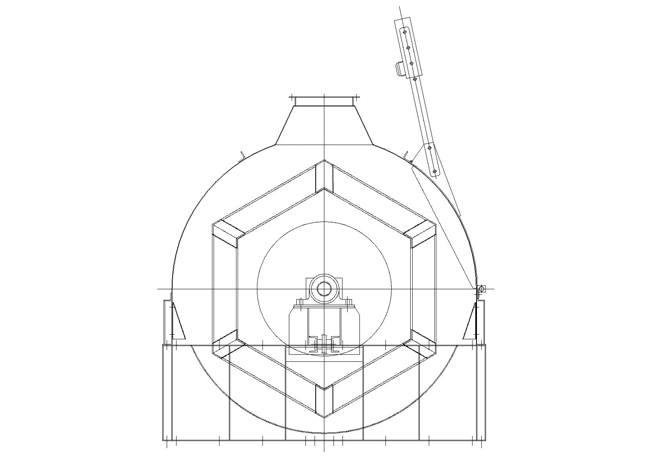

The constant rotation of the sieve drum systematically rolls the conveyed material on the inside of the screen lining, thus achieving a continuous screening operation.

In doing so, the rotational speed and gradient of the drum are decisive variables for the conveying speed and filtering through the screening area, i.e. for the conveying and screening capacity.

A further advantage of rolling the material which is to be conveyed is that any remaining lumps are broken up in the process, resulting in an improved level of screening.

This effect is further enhanced by the polygon sieve version.