Linear vibratory screens

Linear vibratory screens are used for important screening tasks in nearly every industry due to their robust and stable construction.

The linear vibratory screens especially suit for classification of bulk material like ore, coal, sinter, pellets, sand, rocks and stones because of the big screens surfaces which provide an extreme high performance.

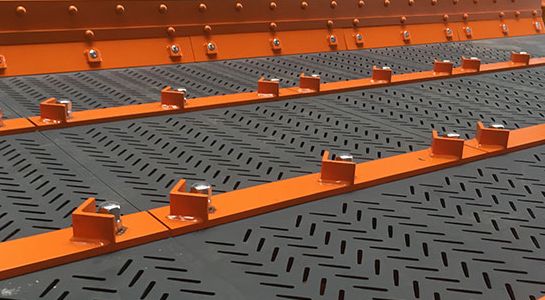

At these screens, special screen grids separate different grain sizes from each other so that the bulk material is sorted in different grain size groups. The capabilities and adaptions of the screens are as enormous as the diversity of bulk materials.

With our know-how and the experience about screening technologies we gained over the last 60 years, we will find the best solution for your individual task and requirements.

The outlets are designed that the different grain sizes will be transported in the corresponding chutes.

There are also optional cover hoods available which seal up the screening machine and allow to run it with dusty bulk materials without harming the environment.

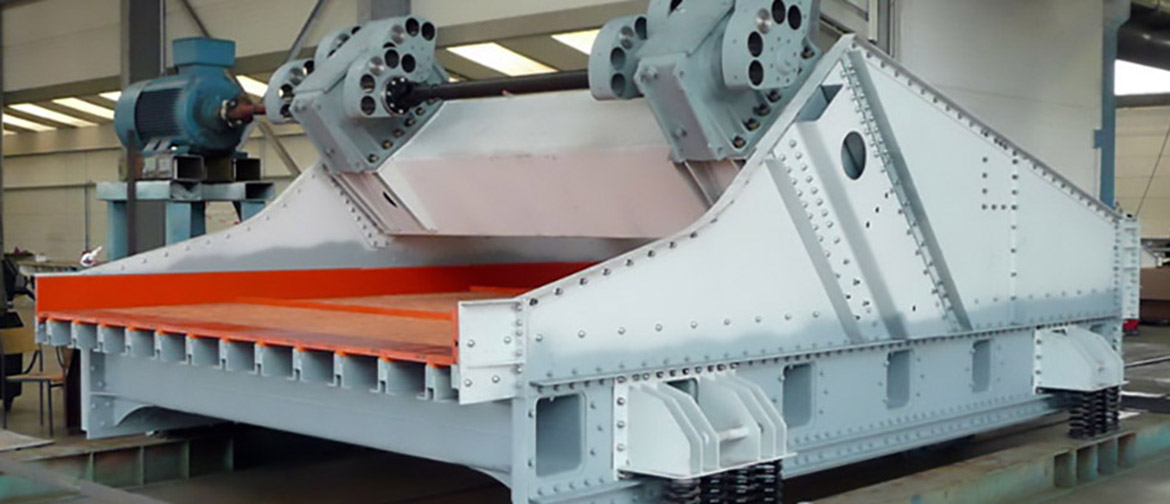

Single Deck Linear Vibratory Screen

Main task of the machine is to split bulk material into two grain sizes.

These High-Performance-vibratory screens are built for high screening efficiency and a fast separation of the fines. Thereby the dimensions and performance can be individually adjusted to your shop floor, requirements and needs.

We will find the most efficient solution for you.

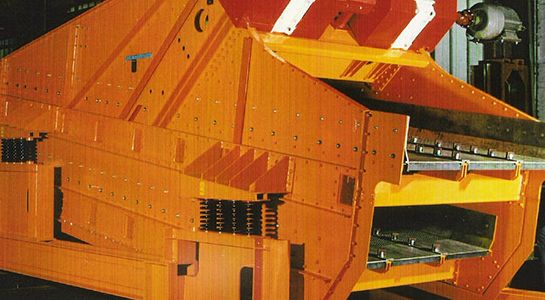

Double Deck Linear Vibratory Screen

Different bulk materials are screened by two screen surfaces (top deck and bottom deck) with varying screen grids.

With two decks you receive three different grain sizes at the end which are separately transported through chutes.

This model of linear vibratory screens are also available as Dewatering Screen and Banana Screen.

Hot Sinter Screen

Due to heat proof materials and very resistant screen grids with special high-temperature-fixation, this linear vibratory screen can handle hot bulk material, like hot sinter, with a temperature up to 900° Celsius.

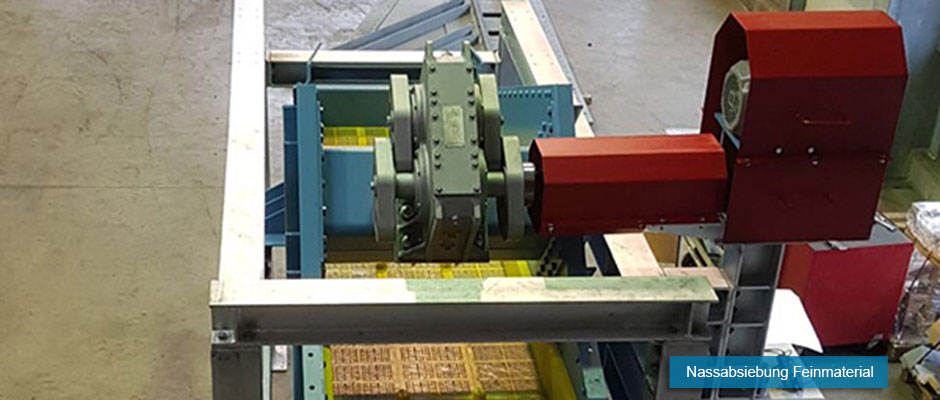

Dewatering Screen

This type of linear vibratory screen is used to wash, dewater, pre-classify and screen wet material as well as remove foreign material.

The dewatering screen can also handle dusty bulk material without contaminating the surrounding with dust.

Banana Screen

The screen obtained its name because of the fruit-like form.

This special model of vibratory screen is applicable for almost every situation, weather it is classification, washing, dewatering, wet screening or screening of the fines.

Due to the banana formed screen body and therewith inclined screen grids, the vibratory screen can process largest amounts of bulk material with high percentage of fines as quick as possible.

The utilized effect at this machine is called "thin bed" screening which realizes a better screen efficiency and a higher throughput rate as linear vibratory screens of the same dimensions.

The banana screen is the best answer when highest performances and optimal screening results are needed.