Multideck-Sizer

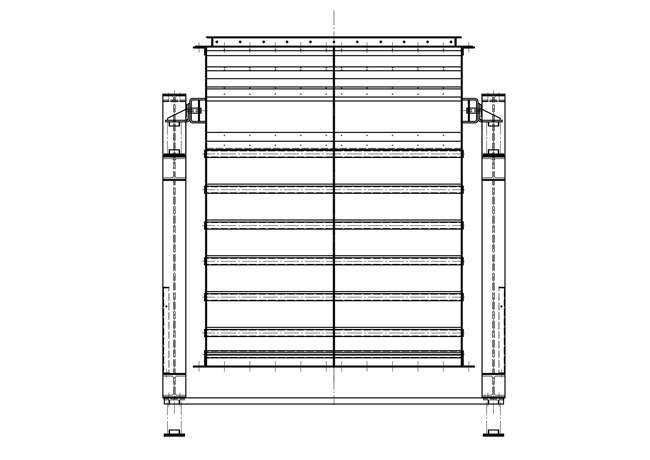

Multideck SIZERS are used in all situations where high screening capacity is required and where several grades have to be screened at once in a confined space.

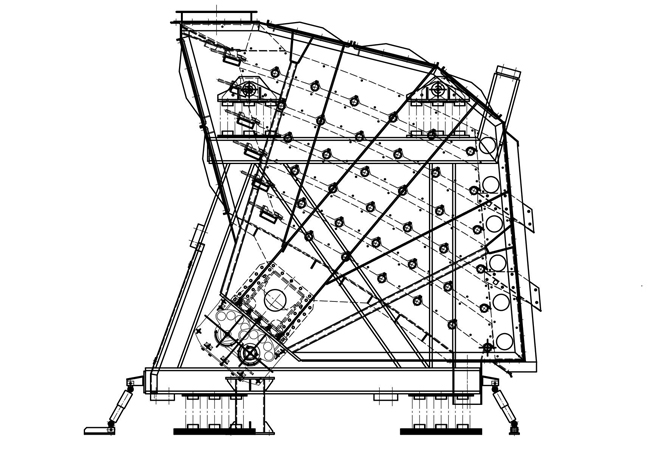

The conveyed product is continuously fed to the SIZER via a belt conveyor or vibrating feeder. As a result of the (up to 6) sieve decks arranged on top of each other, the product is divided up straight away into its grades in an almost 'free fall' fashion. A parabola-shaped unit is used for this.

As such, the usual 'stratification' (which takes place on flat sieves) can be dispensed with.

Here, the following grades are screened by passing through the machine once: 0 – 5 mm, 5 – 10 mm, 10 – 16 mm und > 16 mm.

As a result of their compact design, the SIZERS are fully dust tight, use medium vibrating fibreglass hoods and are enclosed.

Despite the high conveying capacity, the rated capacity is merely 18.5 kW with a speed of 750 min-1.

Through the use of an insulation frame, as a counterweight to the vibrating weight, the dynamic residual forces in the steel construction are reduced to a few kilogrammes.

All surfaces of the SIZER coming into contact with the product are protected against wear and tear using thick Hardox plates.