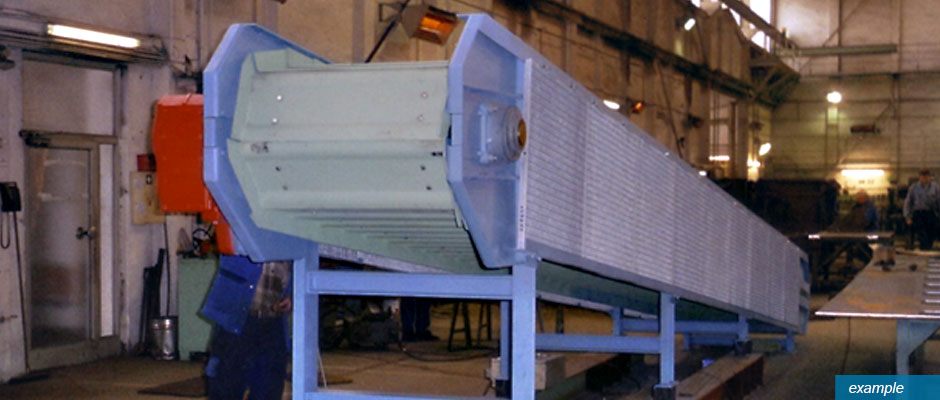

Apron conveyors

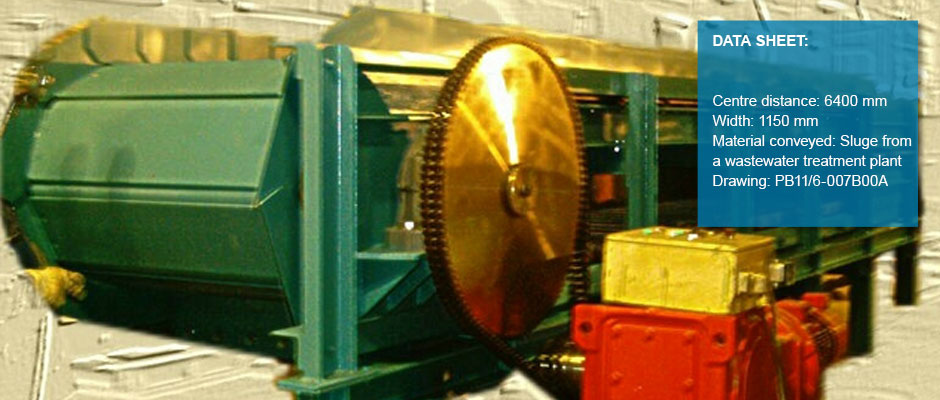

Apron conveyors are put into operation where conventional rubber belt conveyors cannot be used due to the properties of the material conveyed. Among other things, these include large pieces, heavy, sharp-edged parts and hot parts. Apron conveyors are basically composed of the means of transport (plates) in the form of a link conveyor and the tensile member, in most cases a single chain or double-strand chain. Due to the demanding requirements and the weight resulting from the design of the link conveyor, the framework and the runners mounted on it have been configured in such a way as to provide the necessary stability.

Depending on the load and on the ambient conditions, it is possible to design the tensile member (chain) with flange rollers, which can be re-lubricated. This version is recommended for a dusty environment or for operation in the open air. The apron conveyor is powered by a geared motor that is inserted on the drive shaft.

The drive shaft and deflection shaft bearing are mounted using sufficiently sized pedestal bearings which are easily accessible. In order to compensate the polygon effect that can occur in apron conveyors with a larger pitch and to maintain the pretension in the chain, the reverse bearing is mounted on a guided carriage fitted with disk spring washers.